Telephone consultation

400-102-3850

Fuel ethanol

Anhydrous ethanol is widely used in food, chemical, fuel, military, medicine and other fields. The concentration of ethanol from biomass fermentation is generally 3 ~ 20wt%. When the maximum concentration of ethanol after removing most of the impurities such as water, aldehyde and fusel oil by ordinary distillation section reaches 95%, it forms an azeotrope with water, which is difficult to separate by ordinary distillation. In order to obtain anhydrous ethanol, the ethanol must be further dehydrated.

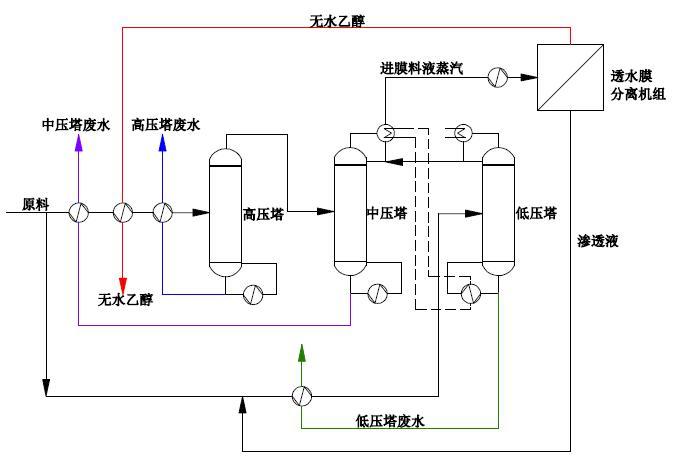

With most of the preheated raw materials as reflux feed from the top of the tower, the high-pressure tower (250kPa(G)) is used to extract the vapor phase, and the tower kettle discharges the wastewater; the ethanol produced by the high-pressure tower enters the medium-pressure tower rectification (200kPa(G)) in the form of vapor phase, and the ethanol vapor (200kPa(G)) with a water content of ~ 15wt; at the same time, a small part of the preheated raw material is mixed with the permeate and then enters the low-pressure tower (-50kPa(G)) for rectification, and ~ 25wt.% of the ethanol liquid taken out from the top of the tower is sent to the top of the medium-pressure tower as reflux, and the tower bottom discharges waste water.

Process advantages

1. The high-pressure tower adopts the stripping method, which does not need additional condensation reflux, reduces energy consumption, and the produced vapor phase products directly enter the medium-pressure tower, avoiding the need for large pressure difference between the medium-pressure tower and the high-pressure tower due to coupling heating;

2. The low-pressure tower is used as a concentration tower to reflux the ethanol raw material after being concentrated as a medium-pressure tower, and the economy of negative pressure distillation is used to further reduce the heat load of the medium-pressure tower. At the same time, the heating load of the low-pressure tower is provided by the condensation at the top of the medium-pressure tower;

3. The vapor phase products extracted from the high-pressure tower directly enter the medium-pressure tower rectification, which greatly reduces the heat load of the medium-pressure tower and provides heat utilization efficiency.