Telephone consultation

400-102-3850

Pharmaceutical Chemical Industry

ethanol recovery

Distillation-Molecular Sieve Membrane Coupling Technology

Case 1:8000 tons/year distillation-molecular sieve membrane coupling ethanol separation device

It is used as a solvent for extracting or cleaning drugs in the process of synthesizing enalapril. The ethanol mother liquor contains acetic acid, sodium chloride, by-products and branched groups in the process of drug synthesis. The mother liquor is yellow, has foul odor, has a conductivity of 600~1000 μs/cm, and has a water content of about 10wt.%. If ethanol is to be reused, the water content needs to be reduced to below 0.4wt.% and colorless and transparent. Originally, the owner used ethylene glycol and potassium acetate as extractants to recover the two mother liquors by extractive distillation respectively. A total of 4 distillation columns with a height of 20~25m were required. Although ethanol meeting the recovery standard can be obtained by using this process, there are problems such as high energy consumption, complicated operation, laborious parking fees, easy blocking of towers for long-term parking, and regular replacement of ethylene glycol. Therefore, the rectification-molecular sieve membrane coupling process technology is adopted for the project, and the acid-base neutralization device, the rectification dehydration and demineralization device and the molecular sieve membrane equipment are integrated in the project to complete the removal of inorganic acid, organic acid and water in ethanol in one step, and finally qualified ethanol with water content ≤ 0.4wt.% and colorless and transparent meeting the recycling and use standards of enterprises is obtained.

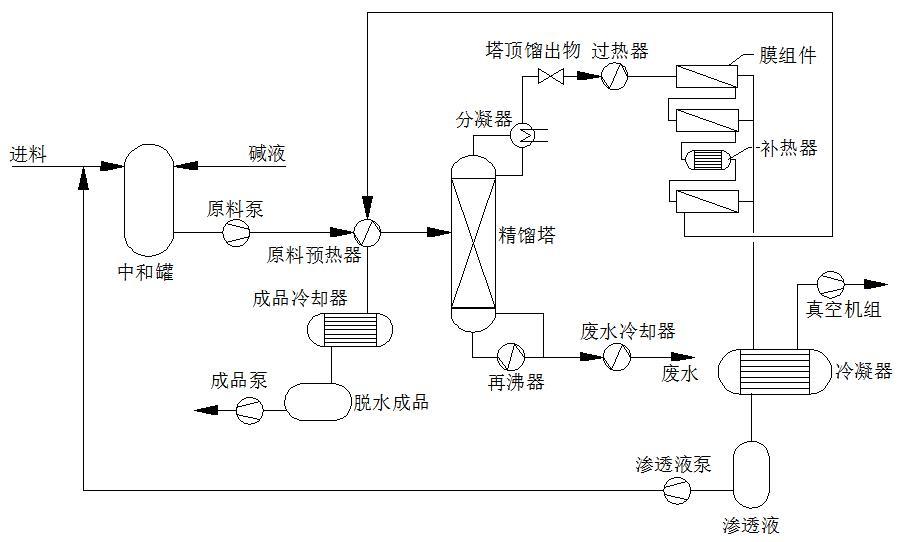

Process flow

Process comparison

Comparison of Enalapril Ethanol Mother Liquor Recovery Process

| Project |

extractive distillation |

distillation-molecular sieve membrane coupling |

| Steam (t/t feedstock) |

1.3 |

0.85 |

| Circulating water (m3/t raw material) |

60 |

45 |

| Low temperature water (m3/t raw material) |

5 |

5 |

| Electricity (kwh/t feedstock) |

10 |

15 |

| Operating cost (yuan/t raw material) |

282 |

194 |

| Yield% |

85~93 |

≥97 |

| Maximum operating pressure (MPa(G)) |

0 |

0.2 |

| Required steam pressure (MPa(G)) |

≥ 1 (recovery tower) |

≥0.4 |

| Installation height of distillation column (m) |

20~25 |

~12 |

| Operator |

4-6 persons/shift |

1~2 persons/class |

| operation complexity |

Complex, requires coordination and cooperation of many people, long start and stop time, and long time for equipment stability |

Simple, only one person can complete the start and stop work, and the equipment can be stable in a short time. |

| Existing problems |

Long-term operation will cause high boiling point impurities and salt in ethanol mother liquor to be mixed with ethylene glycol, which needs to be treated or replaced regularly. After long-term shutdown of the equipment, the tower is easy to be blocked and the cleaning is complicated. |

The molecular sieve membrane has strict control over the raw material properties, which requires high attention and regular testing by personnel, otherwise the membrane tube is easily damaged. |

Enalapril ethanol mother liquor recovery distillation-molecular sieve membrane coupling device

Acetonitrile Recovery

Ceftriaxone sodium is a broad-spectrum long-acting antibiotic listed by Swiss Roche Company in 1982. It has a large market share and is the third generation of cephalosporins with broad-spectrum antibacterial activity. In actual production, when the crude ceftriaxone sodium is prepared from the raw material 7-ACA, acetonitrile is used as the reaction solvent, and after the reaction, the resulting acetonitrile mother liquor is separated to obtain a certain quality index of the recovered acetonitrile again as the reaction solvent for recycling. In the production process, acetonitrile is inevitably mixed with water and other impurities, resulting in acetonitrile waste. Since acetonitrile and water will form azeotrope (the water content of acetonitrile-water azeotrope at atmospheric pressure is about 16 wt.%), the acetonitrile waste liquid cannot be directly separated and refined into a reusable reaction solvent by regular distillation (the water content of solvent acetonitrile is usually ≤ 0.05wt.%). From the perspective of this process route, the quality of recovered acetonitrile plays a decisive role in the quality of ceftriaxone sodium crude product.

In the traditional process of recovering acetonitrile, there are mainly the following four kinds of separation and purification processes: pressure swing distillation method, azeotropic distillation method, salting out method and dehydrating agent method. These methods all use two steps of crude distillation and distillation, and use special distillation methods for separation treatment, which have the problems of complex treatment methods, high equipment cost, low separation efficiency, high energy consumption and low yield of acetonitrile.

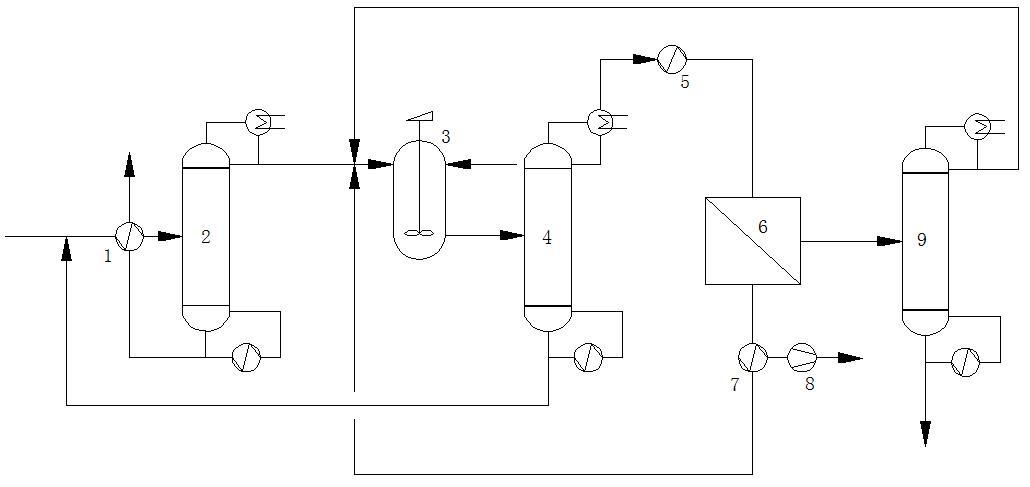

1 is the preheater, 2 is the concentration tower, 3 is the neutralization tank, 4 is the impurity removal tower, 5 is the superheater, 6 is the pervaporation separation unit, 7 is the permeate condenser, 8 is the vacuum pump, 9 is the refining tower.

The acetonitrile waste liquid in the synthesis of ceftriaxone sodium enters the concentration tower, and part of the water and heavy components are removed by distillation; the acetonitrile distillate obtained after concentration is sent to the neutralization tank to adjust the pH; the neutralized acetonitrile distillate is sent to the impurity removal tower for further impurity removal; the acetonitrile distillate enters the pervaporation membrane separation unit after removing impurities in the impurity removal tower; after separation by pervaporation membrane separation unit, the crude product acetonitrile is obtained. The water in the liquid side solution and a small amount of acetonitrile pass through the pervaporation membrane to obtain the permeate in the form of steam. The permeate is condensed and returned to the neutralization tank to recover the acetonitrile again. The crude product acetonitrile obtained by pervaporation separation unit is sent to the refining tower for refining to obtain the finished product acetonitrile, the acetonitrile-water azeotrope distilled off from the purification column is returned to the impurity removal column to recover the acetonitrile therein.

engineering case

Isopropyl alcohol recovery

A distillation-pervaporation membrane coupling technology

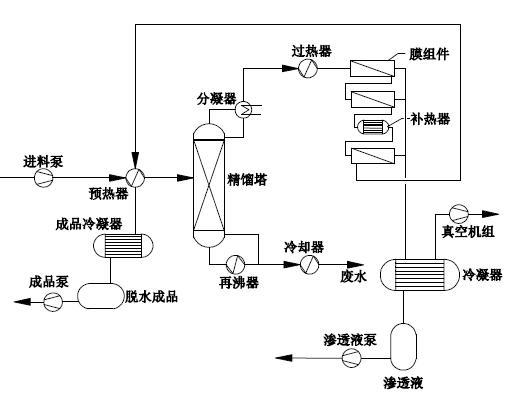

The isopropanol feed liquid from the production process is transported by the feed pump and enters the rectifying tower after heat exchange with the finished film steam in turn, and the pressure in the tower is continuously operated. After stable operation of full reflux, isopropanol vapor with water content of ~ 12wt.% is extracted from the top of the rectifying tower, which is partially condensed by the condenser, flows into the reflux drum, and then transported to the top of the rectifying tower by the reflux pump, and part of the uncondensed isopropanol vapor enters the membrane separation unit after superheating by the superheater. The membrane separation unit is composed of a plurality of membrane modules in series. The moisture and a small amount of isopropanol in the raw material permeate from the upstream side of the membrane to the downstream side of the membrane through the membrane module, and the final stage on the upstream side of the membrane obtains the finished product. The downstream side of the membrane adopts vacuum pumping and condensation to form the vapor partial pressure difference of the components on both sides of the membrane. The permeate vapor enters the condenser under the suction of the vacuum unit, and the condensed permeate is sent to the wastewater treatment. The waste liquid of the distillation tower kettle is cooled by the cooler and sent to the wastewater treatment.

Shenyang Sanjiu Pharmaceutical Co., Ltd. 3000 tons/year distillation-molecular sieve membrane coupling isopropanol separation device.

B adsorption-pervaporation membrane coupling technology

Zhangjiagang Kailing Chemical 34400 Ton Ethanol and Isopropanol Dehydration Project: The enterprise uses isopropyl acetate and hydrogen as raw materials to realize the hydrogenation reaction of isopropyl acetate to generate ethanol and isopropanol through catalyst catalysis. However, in the separation process of ethanol and isopropanol products, the separation process becomes complicated due to the presence of a small amount of water, so the reaction production mixture must be removed from water before further separation can obtain ethanol and isopropanol. In the original process, the reaction solution is sent to the molecular sieve adsorption process for dehydration to obtain anhydrous ethanol-isopropanol mixed solution, which is further refined to obtain the product. However, in the molecular sieve adsorption process, desorption is required after the molecular sieve adsorption is saturated, and the water-containing 2-3% ethanol-isopropanol mixed solution produced by desorption cannot be treated, and the annual production of the water-containing mixed solution is about 34400 tons. If it cannot be effectively recovered, the yield, economic benefits and environmental pressure of the entire production line will be severely tested. For this reason, the enterprise ordered a set of molecular sieve membrane dehydration device of ethanol-isopropanol mixed system with a treatment capacity of 34400 tons/year from Jiangsu Jiutian High-tech Co., Ltd. to treat the desorption liquid generated by the molecular sieve adsorption device, dehydrate the desorption liquid to a water content of 0.3 and then enter the next process to continue the separation of ethanol and isopropanol.

Molecular sieve adsorption-molecular sieve membrane coupling device for the hydrogenation of isopropyl acetate to ethanol and isopropanol

After adopting this technology, it is calculated that 1.2 tons of steam and 90m of circulating water can be saved per ton of product compared with traditional technology.3At the same time, the cost of labor and environmental protection is significantly reduced, and the annual benefit is 9 million yuan, which greatly improves the competitiveness of enterprises in the market.