Telephone consultation

400-102-3850

Integrated Distillation-Membrane Separation Technology

Distillation-membrane separation integration technology is a technology that highly integrates distillation separation and molecular sieve membrane dehydration separation processes to dehydrate and recover organic solvents. Distillation-membrane separation integration technology mainly has two situations: 1) in the molecular sieve membrane equipment before the introduction of distillation equipment, the distillation tower top of the solvent vapor in the form of gas phase directly into the membrane separation system, to achieve the coupling operation of distillation and membrane separation, shorten the process, significantly reduce the molecular sieve membrane equipment secondary evaporation process of energy consumption. 2) After the molecular sieve membrane equipment, the distillation equipment is introduced, and the solvent vapor after dehydration of the molecular sieve membrane equipment is directly introduced into the post-stage refining distillation tower in the form of vapor phase without condensation, so as to realize the coupling operation of membrane separation and distillation, and significantly reduce the energy consumption of the refining distillation tower process.

In addition, Jiutian Gaoke has small-scale and pilot-scale experimental devices for distillation-membrane separation integration technology, has carried out relevant experiments for separation and dehydration of specific solvent systems, has obtained basic data, and has independently developed molecular sieve membrane process calculation software on this basis. The process control system and equipment of distillation-membrane separation integration technology have been developed.

Technical advantages:

1) Through the waste heat recovery of solvent vapor, the process energy consumption can be fully saved, and the energy saving is more than 40% compared with the regular distillation and adsorption process.

2) The high temperature and high pressure steam at the top of the distillation column can directly enter the molecular sieve membrane separation system, which significantly improves the membrane separation efficiency.

3) It is suitable for dehydration of organic solvents with different water content or solvent products with high water content, which broadens the application range of membrane separation dehydration technology.

4) The automatic control system and equipment optimization of the coupling separation process improve the stability of the production process, realize the miniaturization of the coupling device, and reduce the equipment cost and operating cost.

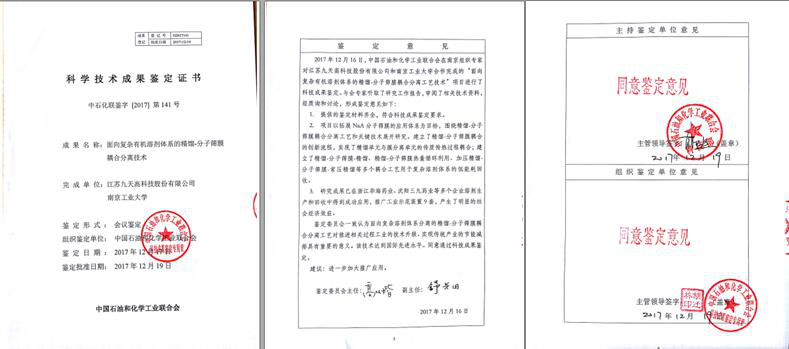

Technical identification:

On December 16, 2017, Sinopec Federation organized an expert group headed by Academician Gao Congyi and Academician Shu Xingtian to appraise the results of "Distillation-Molecular Sieve Membrane Coupling Separation Technology for Solvent Recovery in Complex Systems", believing that "this technology is of great significance to promote the technological upgrading of related industrial processes and realize energy conservation and emission reduction in traditional industries. The technology has reached the international advanced level".

Technical applications:

At present, distillation-membrane separation integrated technology has established 15 sets of distillation-membrane integrated industrial equipment in Shandong, Liaoning, Zhejiang and other places, saving energy and reducing consumption, and bringing huge economic and social benefits to customers.