Technology

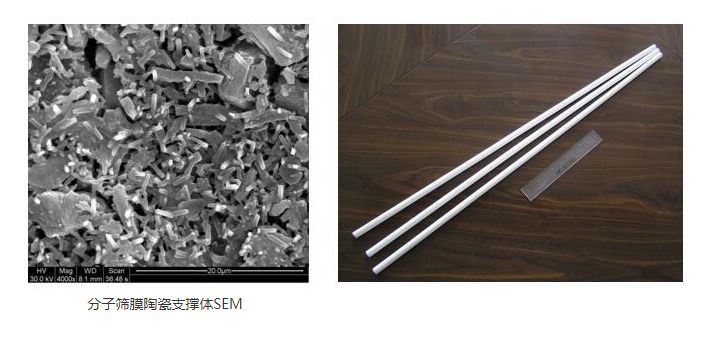

Molecular sieve membrane support

The molecular sieve membrane support is a ceramic support with a porous structure that is sintered at high temperature by alumina, mullite, etc. With the support of the national 863 science and technology project, according to the growth characteristics of the molecular sieve membrane layer, through the modification of the ceramic aggregate, the particle size distribution and the temperature programming control of the sintering process, Jiutian Hi-Tech has successfully developed a support specifically for the molecular sieve membrane synthesis process. technology and products. The pore diameter distribution of the support body is uniform, there is no macropore defect, the surface properties are suitable for the growth of molecular sieve membranes, and the synthesized membrane has high separation performance and good stability.

Product advantages:

1) The pore size distribution is uniform. Conventional supports on the market are generally not specially developed for the synthesis of molecular sieve membranes. The pore size distribution is wide, and there are macropore defects of 5-10 μm; while the molecular sieve membrane is a nanoscale separation process, a small number of macropore defects in the support can easily lead to membrane layer defects and stability. There is a problem with sex. The mullite/alumina composite carrier has uniform pore size distribution (about 1 μm), basically no macropore defects, and the synthesized molecular sieve membrane is dense and stable.

2) The structure and surface properties of the support body can be adjusted, which is suitable for the growth of different types of molecular sieve membranes.

3) High mechanical strength and good wear resistance. The production of the molecular sieve membrane proprietary carrier needs to pass the 6MPa high-strength pressure test, and it is not easy to break during use.

4) Resistant to organic solvents and high temperature. The sintering temperature of the carrier is as high as 1600°C, and it is an inorganic ceramic material with good resistance to organic solvents and high temperature stability.

Product Specifications:

|

product name |

length |

the inside diameter of |

outer diameter |

|

Tubular single channel support |

0~1000mm |

7~8mm |

12mm |

|

Tubular four-channel support body |

0~1200mm |

6~7mm |

20mm |

|

Hollow Fiber Single Channel Support |

0~400mm |

0.3~0.5mm |

1~2mm |

|

Hollow fiber four-channel support |

0~600mm |

0.5~1mm |

3~4mm |