Application field

Coal-to-Methanol Production of Medium and Low Boiling Fusel Oil

Background technique

Methanol is one of the important basic organic raw materials used in the manufacture of various organic products such as methyl chloride, methylamine and dimethyl sulfate. It is also a raw material for pesticides (insecticides, acaricides), medicines (sulfonamides, synamycin, etc.), and one of the raw materials for the synthesis of dimethyl terephthalate, methyl methacrylate and methyl acrylate. At present, the production of methanol is mainly a synthetic method. The chemical reaction formula of the synthesis is: 2H2+CO→CH3OH, and the raw materials mainly come from petroleum and natural gas. In recent years, as the price of oil and natural gas continues to rise, coal chemical industry has gradually attracted attention. Synthesis gas is obtained through coal gasification purification, and the acid gas is removed by low-temperature methanol washing for synthesis to obtain crude methanol.

In the typical process of separation and purification of crude methanol, a four-tower separation and purification process is often used: including a pre-rectification tower, a pressurized rectification tower, an atmospheric rectification tower and a methanol recovery tower. Crude methanol enters the pre-rectification tower, and the top of the pre-rectification tower is sprayed with process water for extraction and rectification. After removing light components (mainly non-condensable gas, dimethyl ether, etc.), methanol and high boiling point components at the bottom of the tower are pressurized Enter the pressurized rectification tower; the refined methanol after the vapor phase condensation at the top of the pressurized rectification tower enters the reflux tank, part of it is used as a reflux of the pressurized tower, and part of it is used as a refined methanol product to exit the device; the methanol at the bottom of the pressurized tower, high-boiling The components and water enter the atmospheric tower, and the refined methanol product is extracted from the top of the atmospheric tower, and the side line is set up under the feed plate to extract. The bottom wastewater enters the biochemical system for treatment. The recovery tower is equipped with a side line to extract low-boiling fusel oil to ensure the quality of methanol at the top of the recovery tower and the total alcohol content in the wastewater at the bottom of the tower, and the wastewater at the bottom of the tower is sent to biochemical treatment. The low-boiling fusel oil extracted from the side line of the recovery tower is mainly composed of methanol, isopropylene ether, n-hexane, ethanol, methyl ethyl ketone, propanol, n-heptane, water, etc. The methanol content is related to the synthesis conditions, and the water content is 30 ~50wt.%. In this part of fusel oil, water molecules and various components form a variety of binary and multiple azeotropes. It is difficult to remove the water by ordinary rectification, and it adds a lot to the further recovery of methanol in fusel oil. big difficulty.

process flow

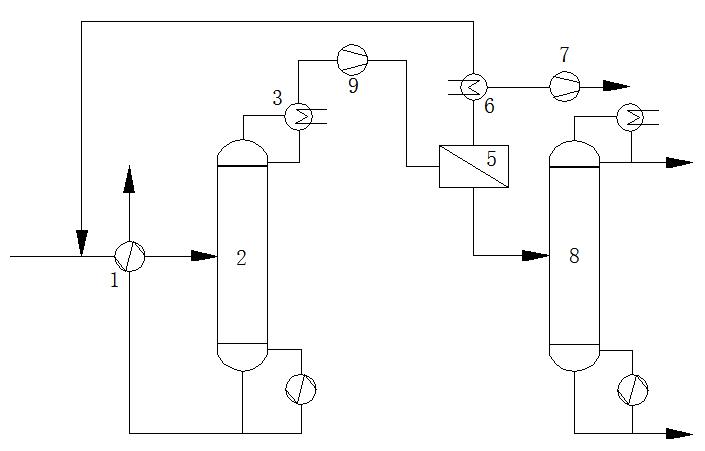

1. Preheater; 2. Thickening tower; 3. Decondenser; 4. Superheater; 5. Pervaporation membrane separator; 6. Permeate condenser; 7. Vacuum unit; 8. Refining tower; 9. heat pump.

The low-boiling fusel oil extracted from the side line of the methanol recovery tower in the refining methanol section enters the concentration tower for concentration, and the fusel oil vapor after preliminary dehydration in the concentration tower is evaporated from the top of the concentration tower and partially condensed for concentration The tower is refluxed, and the rest of the steam is not condensed, and is sent to the pervaporation membrane separator for separation after being heated or passed through a heat pump to obtain 0.01~1wt.% fusel oil dehydration product steam, and the water and a small amount of organic matter in the liquid side solution are in the form of steam The permeate is obtained through the pervaporation membrane, and the permeate is condensed and returned to the concentration tower, and the top product enters the pervaporation membrane separator. The dehydrated product steam of the pervaporation membrane separator is not condensed, and enters the refining tower in the form of vapor phase. The methanol product is extracted from the top of the refining tower, and the raffinate is discharged from the tower kettle for further separation and recovery of organic components.

Syngas to ethanol

Background technique

Ethanol is widely used in national defense chemical industry, medical and health, food industry, industrial and agricultural production. Ethanol production methods include biological fermentation and chemical synthesis. Among them, the production technology of syngas to ethanol in the chemical synthesis method is mature, and the production cost is significantly lower than that of the grain route, which has strong competitiveness and broad development prospects. There are three ways to produce ethanol from syngas, one is to produce ethanol directly from syngas; the other is to produce ethanol through biological process of syngas; Regardless of the ethanol production method, aqueous ethanol is obtained. Due to the azeotropic point of ethanol and water, the traditional method cannot directly obtain absolute ethanol. At present, the production of industrial absolute ethanol mainly adopts methods such as azeotropic distillation, extractive distillation and adsorption separation. These traditional ethanol dehydration methods have problems such as complicated process, high energy consumption and serious pollution.

process flow

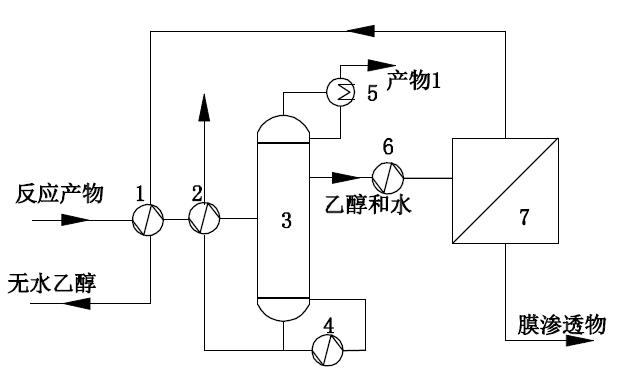

1. First heat exchanger; 2. First heat exchanger; 3. Distillation tower; 4. Reboiler; 5. Top condenser; 6. Superheater; 7. Steam permeable water-permeable membrane equipment; 8. heat pump.

The synthesis gas undergoes a multi-step reaction to obtain a reaction product containing ethanol and water. Before entering the steam permeable membrane, the reaction product is separated in a rectification tower, and ethanol with a water content of 0.1 to 30% is extracted from the top or side line of the last rectification tower Steam: The water-containing ethanol steam is superheated or enters the membrane equipment after passing through the heat pump, and is separated by the membrane module. The membrane outlet (positive pressure side) is the finished product of ethanol with a water content of 0.01-1.

Process advantage

Adopting rectification-steam permeation water permeable membrane equipment coupling technology, coupling traditional technology with new separation technology, not subject to azeotropic restriction, no need to add third components, it is a high-efficiency, energy-saving and environment-friendly separation technology.

Coal-to-ethylene glycol by-product ethanol

As an important basic petrochemical raw material, ethylene glycol is mainly used in the production of polyester fibers, polyester plastics, antifreeze, lubricants, plasticizers, etc. It is also used in industries such as explosives, coatings, and inks, and it can be derived from More than 100 chemicals for a wide range of uses. 5%。 Used in the production of polyester, antifreeze, fine chemical products accounted for about 94% of the total consumption, 2.5%, 3.5%.

The indirect synthesis of ethylene glycol mainly includes methanol dehydrogenation dimerization method, dimethyl ether oxidative coupling method, glycolic acid method, formaldehyde condensation method, formaldehyde hydroformylation method and oxalate hydrogenation method. The hydrogen method is currently the most widely used and researched coal-to-ethylene glycol technology.

The coal-based oxalate method produces syngas through coal gasification, and at the same time uses alcohols and N2O3 to react to form nitrite; nitrite is oxygen-coupled on a Pd catalyst to obtain oxalic acid diester; oxalic acid diester is produced through catalytic hydrogenation diol. Among them, methanol and ethanol are the most studied alcohols.

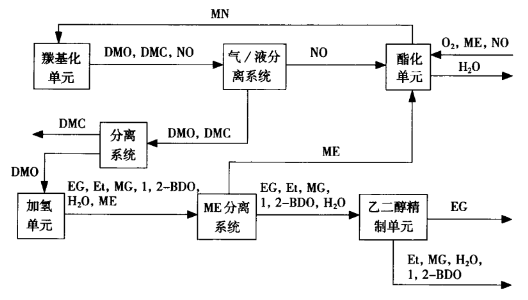

The production of ethylene glycol by hydrogenation of oxalate is mainly composed of four units: esterification unit, carbonylation unit, hydrogenation unit, and ethylene glycol refining. The function of the esterification unit is to oxidize the NO produced by the carbonylation unit and the methanol ME obtained by the hydrogenation unit to obtain methyl nitrite. The function of the carbonylation unit is to carry out the catalytic coupling reaction of CO and methyl nitrite MN to obtain the intermediate product dimethyl oxalate DMO, and at the same time, the reaction generates NO and returns to the esterification unit through the separation system. A small amount of dimethyl carbonate DMC produced by this unit is separated from DMO by the separation system. The function of the hydrogenation unit is to hydrogenate DMO to obtain the crude product of ethylene glycol EG, and react to produce ME at the same time, which is returned to the ester through the ME separation system. unit. The unit produces a small amount of hydrogenated crude products such as methyl glycolate MG, ethanol Et, water and 1,2-butanediol as by-products. The refining unit is to refine crude EG products to obtain polyester grade EG and frozen grade EG products.

In addition to polyester grade EG and frozen grade EG products, this process will eventually produce a by-product consisting of ethanol Et, methyl glycolate MG, water and 1,2-butanediol. For an industrial plant with an annual output of 200,000 tons of ethylene glycol, the ethanol by-product produces about 10,000 tons. If the ethanol by-product can be recovered, the profit of the process can be effectively increased.

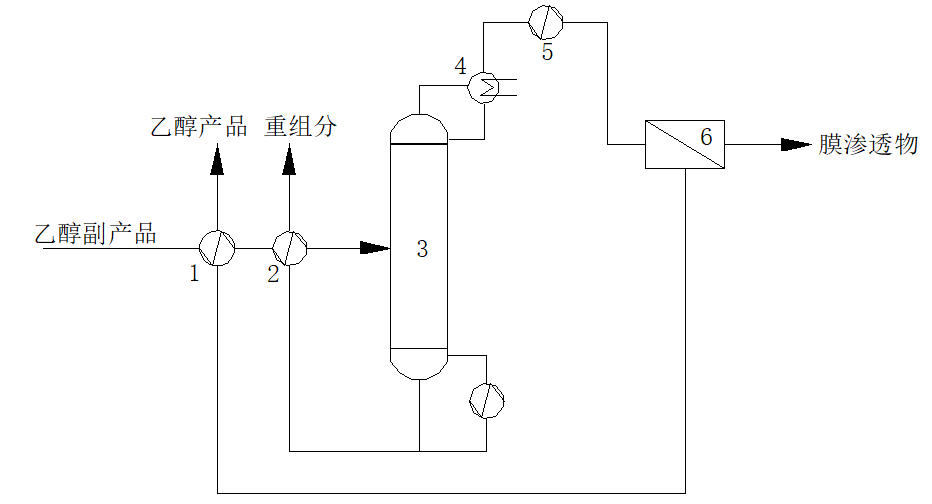

process flow

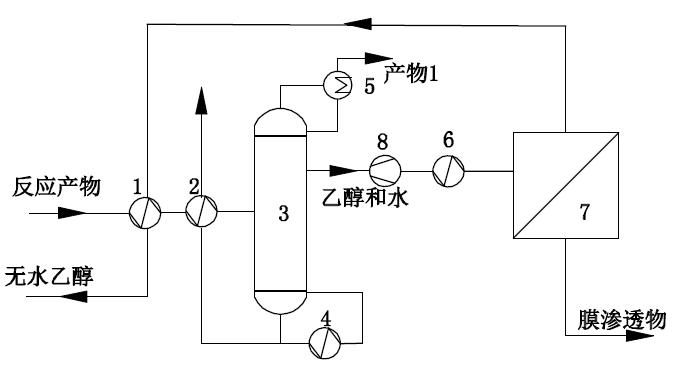

1. First heat exchanger; 2. First heat exchanger; 3. Distillation tower; 4. Decondenser; 5. Superheater; 6. Steam permeable membrane equipment.

The ethanol by-products produced by this process are first separated in the rectification tower to remove high-boiling impurities such as methyl glycolate and 1,2-butanediol in the by-products. The ethanol vapor containing a small amount of water is extracted from the top of the rectification tower. The ethanol steam enters the membrane equipment after being superheated or passed through the heat pump, and is separated by the membrane module, and the membrane outlet (positive pressure side) is the finished ethanol product.